A Complete Guide to Diamond Wire Cutting of Lenses

Introduction:

Welcome to our comprehensive guide to diamond wire lens cutting. In this article, we will explore the world of lenses, discuss why diamond wire loop cutting is the preferred method for lens cutting, and provide a step-by-step guide on how to effectively cut lenses using this method. In addition, we will highlight some important considerations to keep in mind during the process. Whether you are a professional lens cutter or a DIY enthusiast, this guide will provide you with the knowledge and techniques you need to achieve precise lens cutting results.

What is a lens?

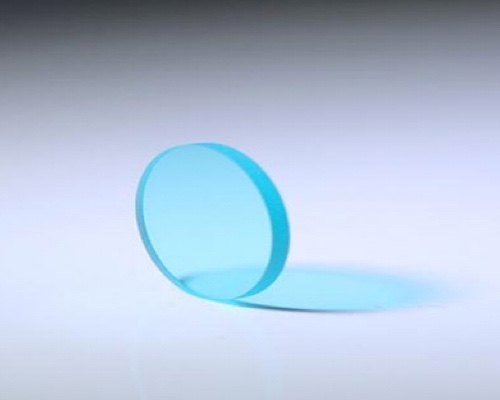

Lens are transparent optical devices with curved surfaces that control the passage and focus of light. They are commonly found in various optical systems, such as cameras, microscopes, telescopes, and eyeglasses. Lenses can be made of different materials such as glass, plastic, or synthetic materials, and they come in a variety of shapes and sizes depending on their specific application.

Why choose diamond wire cutting for lenses?

Diamond wire cutting is the preferred method for lens cutting due to its precision, efficiency, and ability to handle delicate materials. Lenses, especially those made of glass or premium optical materials, require precise and clean cuts to maintain their optical properties. Diamond wire, equipped with a diamond-coated blade, Provides superior cutting accuracy and minimizes the risk of chipping or damaging the lens surface.

Unlike traditional cutting methods, diamond wire cutting allows for greater control over the cutting process, allowing for intricate designs and complex shapes. The high-speed rotation of the diamond-coated blade combined with water cooling ensures that heat generation is minimized, reducing the chance of thermal stress on the lens.