Advantages of Diamond Wire Loop Colored Crystals:

1.Precision and Efficiency

Superior precision: Diamond wire loop cutting enables precise and intricate cuts, ensuring the desired shape and size of colored crystals.

Improved efficiency: With diamond wire loop cutting technology, faster cutting speeds can be achieved, reducing production time and increasing productivity.

2. Minimum material loss

Reduced waste: Diamond wire loop cutting minimizes material loss during the cutting process, maximizing the yield of valuable colored crystals.

Cost-effectiveness: By minimizing waste, diamond wire loop cutting helps optimize the use of raw materials, reducing overall production costs.

3.Versatile

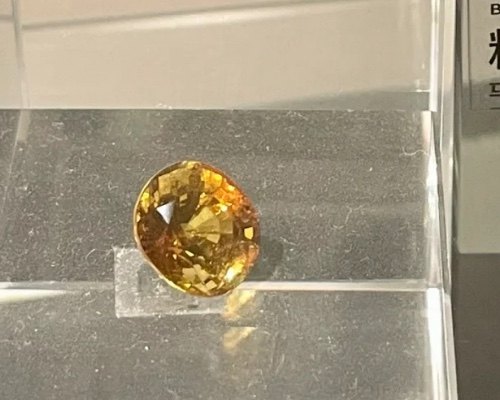

Adaptable to a variety of crystal types: Diamond wire loop cutting technology can be applied to a wide range of colored crystals, including sapphire, emerald, ruby, and amethyst, among others.

Customization options: The flexibility of diamond wire loop cutting allows for the creation of custom shapes and designs, catering to the preferences of individual customers.

4.Improved surface finish, smooth polishing effect

Diamond wire loop cutting produces clean and smooth cuts, Minimizes the need for additional polishing or finishing.

Enhanced clarity and brilliance: The precise cuts achieved through diamond wire loop cutting enhance the clarity and brilliance of the crystal, showcasing its natural beauty.

5. Reduced risk of damage

Minimized fractures: Diamond wire loop cutting minimizes the risk of breaks and chipping, ensuring the integrity of the colored crystal.

Reduces heat generation: Diamond wire loop cutting generates less heat than traditional cutting methods, reducing the possibility of thermal damage to the crystal.

Conclusion:

In this blog, we explored the world of colored crystals and their unique characteristics. We also delved into the revolutionary technology of diamond wire cutting, which delivers precise and efficient results. By utilizing diamond wire, professionals can unlock the full potential of colored crystals, enhancing their brilliance and value. Whether it is sapphire, emerald, ruby, or amethyst, diamond wire cutting has become an indispensable tool in the field of crystal manufacturing. As the demand for custom-cut colored crystals continues to rise, diamond wire cutting will undoubtedly play a key role in meeting these requirements, revolutionizing the industry and inspiring new possibilities in creativity and design.

If you have any custom requirements, We have a dedicated research team and can provide ODM (Original Design Manufacturing) services. We invite you to contact us for further consultation.