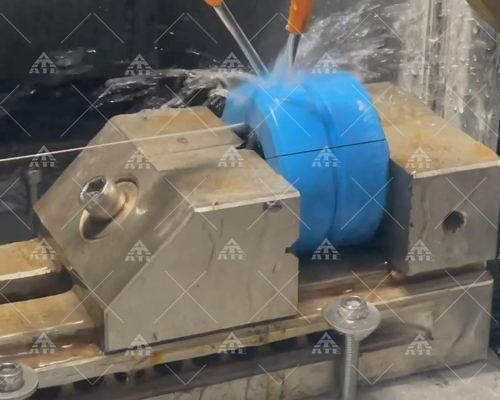

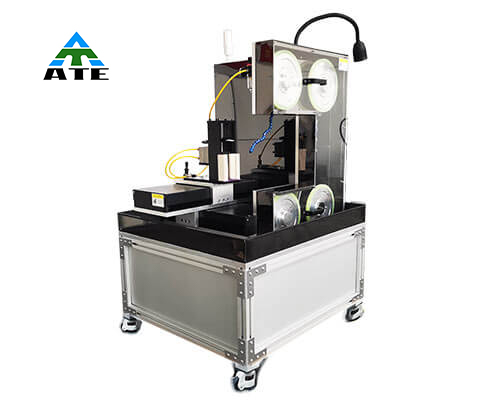

1. Processing of hard and brittle materials

Applicable to cutting high-hardness and brittle materials such as ceramics, glass, and sapphire, especially good at processing ultra-thin samples (the thinnest can be as thin as 0.08 mm), widely used in materials science and industrial precision processing.

In the semiconductor industry, it is used to cut wafers such as single crystal silicon and silicon carbide to ensure the high-precision requirements of chip manufacturing.

2. New energy and photovoltaic industry

Used for cutting polycrystalline silicon and monocrystalline silicon wafers in the production of solar panels, and improving efficiency and reducing material loss through high-speed grinding of diamond wire.

3. Scientific research and laboratory analysis

Support the laboratory to prepare ultra-thin slices of samples such as rocks, minerals, and meteorites to meet the scientific research needs of geology, material analysis, etc.

Can cut composite materials such as PCB (printed circuit board) and epoxy board, and assist in the research and development of electronic components.

4. Jewelry and special material processing

Precisely cut high-value materials such as gemstones and jade to reduce the risk of damage during processing.

Suitable for fine cutting in special fields such as dental materials and biomimetic composite materials.

5. Industry and construction fields

Processing refractory bricks, honeycomb ceramics and other building materials to meet the cutting needs of high temperature and corrosion resistant scenes.

Diamond wire cutting machines have become indispensable key equipment in the fields of semiconductors, photovoltaics, scientific research and high-end manufacturing due to their high precision, low loss and wide material adaptability.