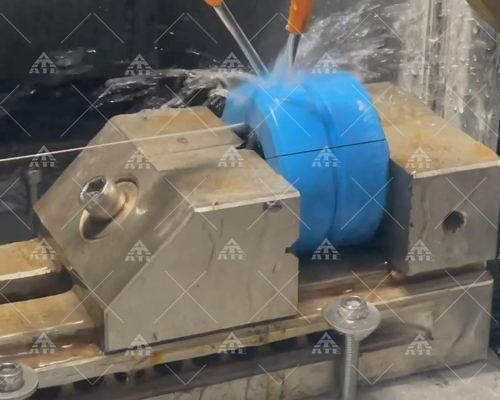

Diamond wire cutting machine, a high-tech equipment with diamond wire as cutting tool, is gradually becoming the core equipment in the field of silicon material processing. Its working principle is similar to that of a hacksaw, and the diamond wire is driven to cut by a winding drum with high-speed rotation and reciprocating motion. This machine adopts a one-way cycle or reciprocating cycle motion mode, so that the diamond wire and the object to be cut form a relative grinding motion, thereby achieving the purpose of precise cutting.

In the process of cutting silicon, the sharp edge of the diamond wire contacts the surface of the silicon material, generating friction, and then gradually grinding away the silicon material to achieve cutting. This process requires extremely high precision and stability, because silicon materials have high hardness and brittleness, and traditional mechanical processing methods are difficult to achieve ideal cutting effects. Diamond wire cutting technology just makes up for these shortcomings. It can provide higher cutting efficiency and better surface quality, greatly reducing material loss.

With the advancement of science and technology, the requirements for the quality, efficiency and material loss of silicon wafer cutting are constantly increasing, and diamond wire cutting machines are also constantly being optimized and upgraded. For example, the MaxEdge system launched by Applied Materials uses a unique two-group independently controlled cutting component, which can increase production while maintaining speed, and can achieve a minimum cutting accuracy of 80μm. Such improvements not only improve production efficiency, but also reduce the cost of solar power.

Diamond wire cutting machines, with their unique advantages, play an increasingly important role in the precision processing of silicon materials, and their application prospects are undoubtedly broad.