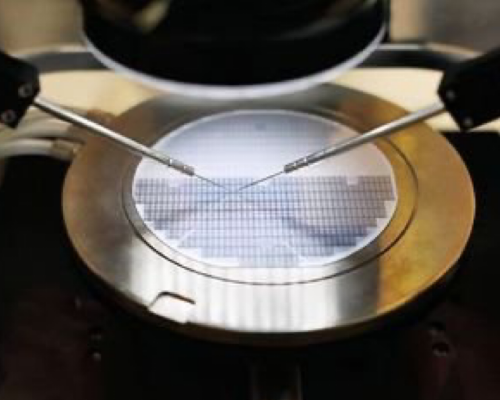

Diamond wire cutting machine is an advanced cutting tool, which occupies an important position in the field of material processing with its high efficiency and precision. It uses the unidirectional circulation or reciprocating circulation of diamond wire to form a relative grinding motion between the diamond wire and the object to be cut, so as to achieve the purpose of cutting. This technology is widely used in the cutting of various hard materials, including but not limited to crystals, ceramics, glass, refractory materials, rock samples, mineral samples and building materials.

The working principle of diamond wire cutting machine is based on the micro-cutting motion of abrasives, which involves the “rolling-embedding” mechanism. In this process, diamond abrasives roll along the cutting surface and squeeze and embed into the surface of the material, thereby producing flaking chips and surface cracks, and finally achieving macro-cutting effect. This cutting method not only improves the cutting accuracy, but also significantly reduces the loss of materials.

In addition to common non-metallic materials, diamond wire cutting machine can also be used for cutting and processing of metal materials, carbon fiber and other fiber materials. Different material types and requirements determine the choice of cutting process. For example, metal materials usually use flame cutting, laser cutting and other methods; while for lightweight and high-strength materials such as carbon fiber, laser cutting and water jet cutting are more suitable choices.

These diverse cutting processes demonstrate the flexibility and wide application of diamond wire cutting machines in modern material processing.