Diamond wire cutting machine is an efficient and precise cutting tool, mainly used for cutting various hard materials.

Its core is to use the high hardness and wear resistance of diamond wire, through unidirectional circulation or reciprocating circulation, to form a relative grinding motion with the object to be cut, so as to achieve the purpose of cutting.This cutting method is not only efficient but also precise, and can meet the processing needs of various complex materials.

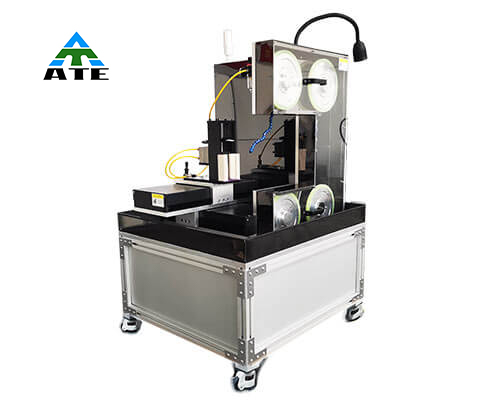

The details are as follows:In terms of working principle, the diamond wire cutting machine is similar to the cutting method of the bow saw.The high-speed rotating and reciprocating wire drum drives the diamond wire to reciprocate, and is tensioned by two tensioning wire wheels at the same time.In order to ensure the cutting accuracy and surface shape, a guide wheel will be added.

By automatically controlling the workbench to continuously feed in the direction of the diamond wire control console, or controlling the diamond wire control console to continuously feed in the direction of the workbench, grinding is generated between the diamond wire and the object to be cut to form a cutting.

Since the diamond wire has a small diameter and is elastic, a micro-arc is formed during the cutting process, so that the force applied to the object being cut, combined with the relative movement between the diamond wire and the object being cut, allows the cutting to proceed continuously.

The application range of diamond wire cutting machines is extremely wide.It can cut conductive and non-conductive materials as long as the hardness is smaller than that of the diamond wire.

Therefore, it is widely used in cutting various metal and non-metal composite materials, such as ceramics, glass, rocks, gemstones, jade, meteorites, single crystal silicon, silicon carbide, polycrystalline silicon, refractory bricks, epoxy boards, ferrites, PCBs, as well as building materials, dental materials, biological and biomimetic composite materials, etc.It is particularly suitable for cutting various brittle crystals with high hardness, high value, and easy to break, such as semiconductor material silicon carbide (SiC).

These materials are widely used in aerospace, electronics industry, photovoltaic industry and other fields.

Diamond wire cutting machines also have many unique advantages.For example, it has high cutting accuracy and can meet the cutting requirements of most materials; it has a wide range of uses and can cut large samples as well as small samples; it has a sophisticated design and largely meets the cutting requirements of most samples.At the same time, it can also be designed with various tooling fixtures as needed to meet different cutting needs.It should be noted that when using a diamond wire cutting machine, it is necessary to strictly abide by the relevant safety operating procedures to ensure the safety of personnel and the normal operation of the equipment.At the same time, it is also necessary to select appropriate diamond wires and cutting parameters according to the specific material properties and cutting requirements to achieve the best cutting effect.

Diamond wire cutting machine is a powerful and widely used cutting tool that plays an important role in modern manufacturing and scientific research.