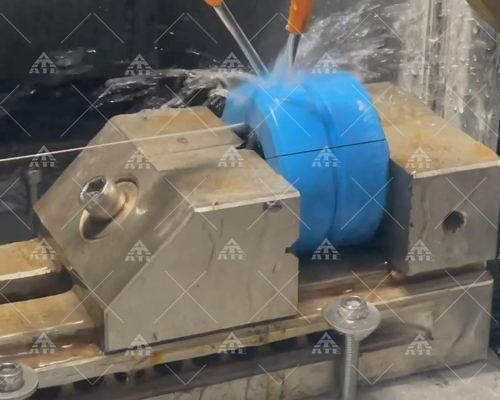

1. The integrated body structure adopts a high-strength cast iron molding base as the load-bearing component of the machine tool to ensure that the equipment will not be affected by its own hardness during processing and use, thereby increasing the durability and stability of the equipment.

2. The X and Y axes adopt imported high-precision linear guides and high-precision ball screws to ensure the stability of the equipment during processing. The wire drum is made of polyurethane material, which is durable and wear-resistant. Whether at high or low speed, it can ensure the smooth operation of the sand wire and accurate line arrangement to ensure the processing quality.

3. The counterweight device is upgraded from the original single guide rail to a high-precision double guide rail effect, which is sensitive in operation, higher in precision, and more stable in sand wire tension. The shaft is upgraded, the axis is thickened to 50mm in diameter, the bearing capacity is better, and the bearings are increased to 3 to ensure that the workpiece is more stable during rotary cutting.

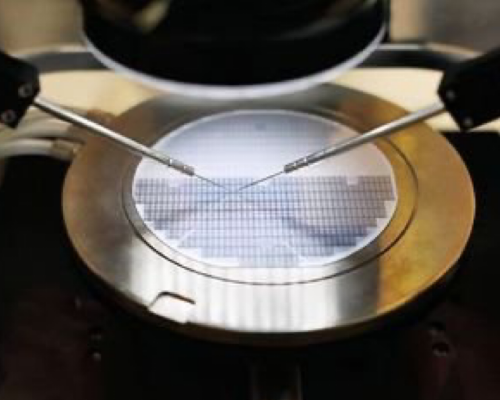

With the development of intelligence, the grassroots operators of machine tools face severe tests. Machines replace people to do simple work, and through the clever design of robots, they can make greater efficiency in a short time. For diamond wire machine tools, it is a greater challenge, especially the development of multifunctional composite, which improves the efficiency and processing accuracy of machine tools and improves the flexibility of production. It has the characteristics of simple structure, low cost, good process effect and low consumption during use. The improvement of cutting technology has enabled the production process of wire cutting equipment manufacturers to be better applied and developed, that is, the correlation between technological progress and application expansion has greatly improved the flexibility of application.