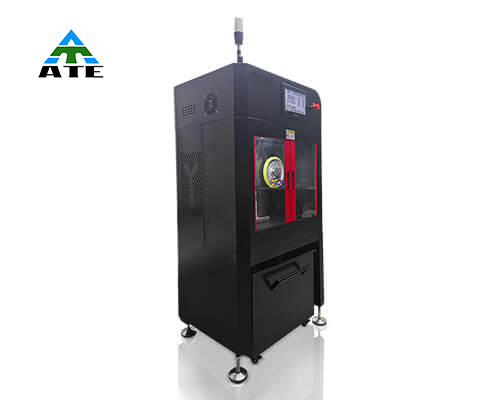

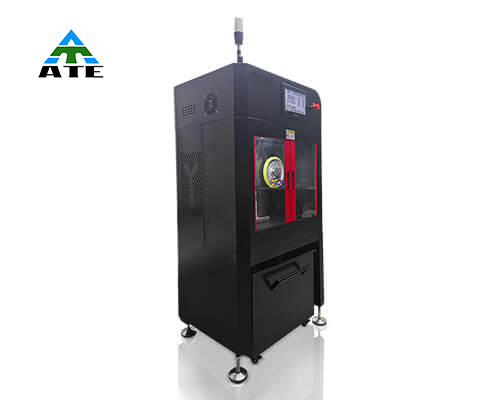

Endless diamond wire cutting machine is suitable to cut almost all kinds of material such as Glass, Rock, Jade, Silicon, Graphite, Sapphire, Metal, Gemstone, Quartz, Ceramics and so on, Especially for Cutting High-value Hard Brittle Materials.

1,Vertical cutting method. 2,The surface is waterproof which can do wet cut.

3,The tensioning system adopts adaptive tensioning system, there is no need to make tension force calculation.

Tel:

+86 175 1317 8882Whatsapp:

+8617513178882Endless Diamond Wire Loop Saw Cutting Machine has a closed-loop diamond wire that can move in a single direction without the need for reversing. The circular diamond wire enables high linear speeds, reaching even up to 60 m/s. As a result, it allows for fast cutting speeds and maintaining superior cutting surface quality. Say goodbye to outdated cutting methods and welcome the future of optical glass cutting machine with our cutting-edge Endless Wire Saw. Specifically engineered to address the limitations of traditional inner diameter saws, the Endless Diamond Wire Loop Saw Optical Glass Cutting Machine sets new standards in efficiency, precision, and versatility.

Endless diamond wire cutting is a flexible cutting which reduce edge breakage rate 60%↓.

Less kerf loss due to thinnest 0.25 mm diameter.

One-way cutting will make the cutting surface really smooth, Endless diamond wire is as thin as 0.3mm.

Diamond grains are fully and continuously coated on the wire with cutting efficiency ↑65%.

With high cutting speed(Max 60m/s) greatly improving work efficiency.

Can cut any material with a hardness lower than diamond( non-conductive materials. semiconductor materials, and conductive brittle materials.)

Diamond wire cutting has high efficiency, precision, and wear resistance; One person can operate multiple devices, saving 85% labor costs.

Materials diamond wire loop cut: Sapphire, Glass, Artificial crysal, Silicon, Magnetics, New material, Gem-stone, Ultrathin marble, Granite, Foamed aluminium, Rock wool, Foam cement, Ceramic, Graphite, Tire, Hollow brick, Corrugated paper, etc.

1, For the cutting of precious materials such as emerald, crystal, malachite, meteorite. The cutting kerf is small and the cutting speed is fast.It is suitable for the processing of various bracelets, pendants and annular section.

2, NdFeB, ferrite, samarium cobalt, alnico and other metal and non-metallic magnetic materials processing, the equipment has high safety, simple operation, large single cutting volume, whoes effiency is several times that of ID saw.

3, The cutting speed of crystal materials such as optical glass is fast, and the cutting surface is smooth and flat, replacing grinding with cutting.

4, Universities,enterprises,research institutes that need to cut a large number of new materials. This is a small equipment with fast cutting speed, high cutting precision and low material loss.

In addition, our cutting equipment can also be used for cutting Various metal and non-metallic composite materials, glass, rock, jade, monocrystalline silicon, silicon carbide, ceramics Epoxy board and other materials, especially suitable for cutting high priced and easily broken high hard brittle materials!lf you have material cutting needs, you can contact us!

| Diamond Wire Loop Parameters | ||||||

|

Outer Diameter (mm) |

Core Wire (mm) |

Grain Size EN |

Tensile Strength (N) |

Recommend Loop Length (mm) |

Max Loop Length (mm) |

Cooling |

| 0.3 | 0.24 | D25 | 60-80 | 1000-3000 | 30000 | Dry/Wet |

| 0.35 | 0.24 | D46 | 60-80 | 1000-3000 | ||

| 0.45 | 0.3 | D46 | 80-100 | 1000-6000 | ||

| 0.5 | 0.36 | D76 | 100-120 | 1000-6000 | ||

| 0.6 | 0.39 | D107 | 100-120 | 1000-6000 | ||

| 0.8 | 0.51 | D126 | 180-200 | 1000-6000 | ||

| 1.8 | 1.2 | D213 | 200-300 | 2500-1000 | ||

| 2.5 | 2 | D213 | 300-400 | 2500-10000 | ||

Aite is a high-tech enterprise specializing in the R&D and production of Endless diamond wire saw ,single diamond wire saw.