Silicon carbide wafer applications and future development trends

Silicon carbide (sic) is the main development direction of the power semiconductor industry, and its application in power device manufacturing can significantly improve power utilization. In the foreseeable future, new energy vehicles will be the main application scenario of silicon carbide power devices .

Compared with traditional silicon materials, silicon carbide is a typical representative of the third generation of semiconductor materials. It has the characteristics of wide bandwidth, high temperature resistance, high voltage resistance, high frequency, high power and radiation resistance.

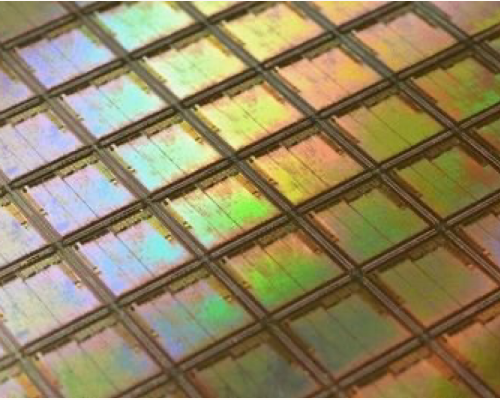

It has the advantages of fast switching speed and high efficiency, which can greatly reduce product power consumption, improve energy conversion efficiency, and reduce product volume. It will become the most widely used basic material for manufacturing semiconductor chips in the future.

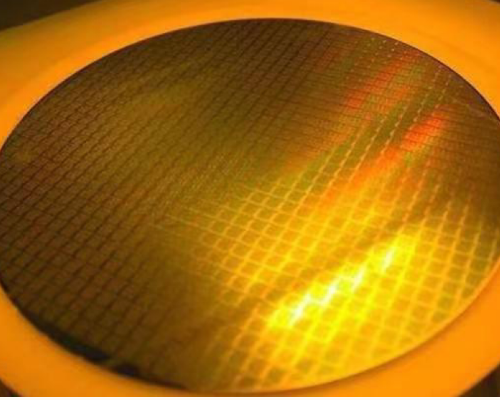

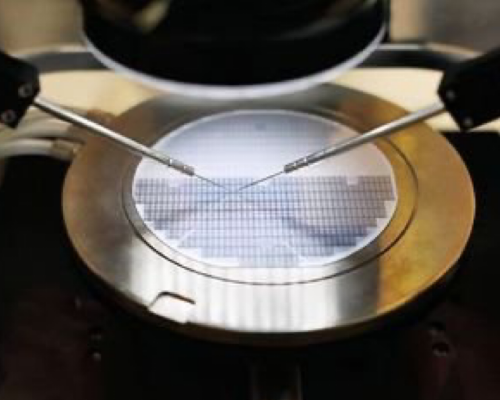

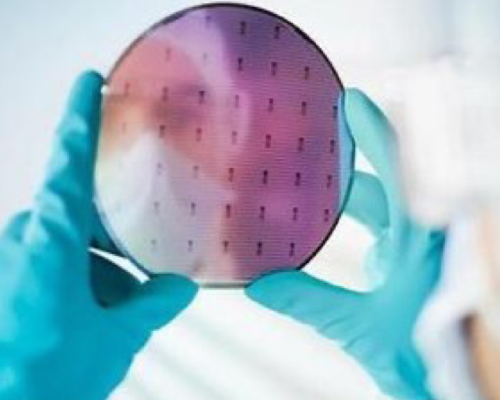

Silicon carbide wafer is a single wafer formed by cutting, grinding, polishing and cleaning silicon carbide crystals. As a semiconductor substrate material, silicon carbide wafer can be made into silicon carbide-based power devices and microwave radio frequency devices through epitaxial growth and device manufacturing. It is the first Important basic materials for the development of the third-generation semiconductor industry.