Simple understanding of industrial sapphire

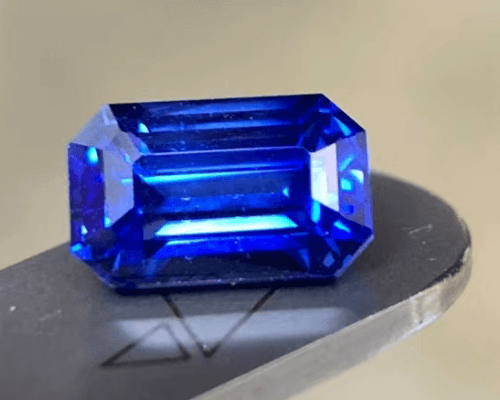

In the gem world, all kinds of gem-grade corundum except ruby are called sapphire. The main component of sapphire is aluminum oxide (Al ∈ O;). Because it contains trace elements such as iron and titanium, it appears as blue, sky blue, light blue and other colors.Our company has senior sapphire cutting technology, and the sapphire cutting machine developed is far ahead in the industry.

Industrial sapphire generally refers to gems that cannot reach the level of decoration, taking industrial diamond as an example. The gear shafts of good mechanical watches are all made of diamonds,However, this kind of diamond can only be used for tools, not for decoration. For example, glass knives, diamonds of blades are also diamonds. The fact is the same. Whether it is artificial or natural, and its level does not reach the level of decoration, it is used for industrial purposes.

Industrial-grade sapphire is mainly used for two purposes:

One is the substrate, such as LED semiconductor substrate material. The second is window materials, such as dials, aerospace, precision manufacturing, etc.

Large-size flat sapphires used in the aerospace field, large-size high-quality sapphires, graphene, night vision infrared transmission equipment, satellite space technology and mobile phone screens in the semiconductor field, optoelectronics field and military field also belong. This is also due to the high temperature resistance, corrosion resistance, high strength, high hardness, good wear resistance, high insulation, good airtightness, good thermal insulation and other characteristics of corundum gemstones. This gem is very cheap, a few dozen yuan a piece. The better the quality, the higher the price. Similarly, high-tech fields require higher quality sapphires.

Sapphire processing technology:

Seed crystal – long crystal – orientation – pull rod – rolling and grinding – quality inspection to obtain mature crystal rods.