The endless diamond wire saw presents significant environmental advantages compared to other cutting technologies, such as water jet cutting or internal circular slicing machines. The key environmental benefits stem from the unique characteristics of this cutting machine.

1,Low Heat Generation:

The utilization of an extremely fine diamond wire as the cutting tool minimizes heat generation during the cutting process. This is in stark contrast to some traditional methods that may produce higher levels of heat. The reduced heat contributes to energy efficiency and mitigates potential environmental impacts associated with heat emissions.

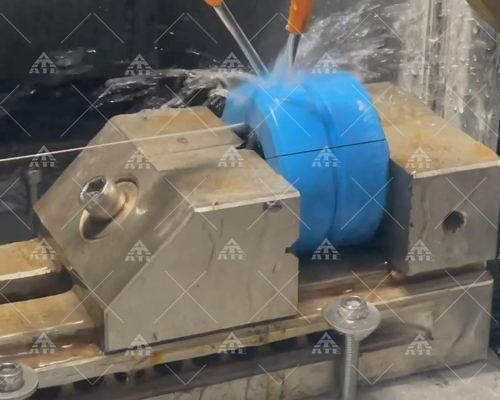

2,Water Circulation System:

The incorporation of a water tank with a circulating water system further enhances the environmental friendliness of the endless diamond wire saw. This system not only aids in maintaining optimal cutting conditions but also serves as an effective cooling mechanism. The use of water as a coolant minimizes the risk of thermal damage and ensures a smoother cutting process.

3,Pollution Reduction:

The closed-loop nature of the diamond wire, typically within 10 meters, eliminates the need for extensive lengths of cutting material. This reduces waste and contributes to a cleaner working environment. Additionally, the fine precision of the diamond wire minimizes the generation of waste material during the cutting process, further reducing the overall environmental impact.

4,Versatility Across Industries:

The adaptability of the endless diamond wire saw across various industries, such as semiconductor, solar, and optical, introduces a potential shift towards a more sustainable and environmentally conscious cutting solution. As a cutting-edge technology, its applications continue to expand, offering a versatile and eco-friendly alternative to conventional cutting methods.

In summary, the endless diamond wire saw, with its low heat generation, water circulation system, and reduced pollution footprint, stands as an environmentally advantageous cutting solution. This aligns with contemporary efforts to adopt cleaner and more sustainable practices across industrial sectors.