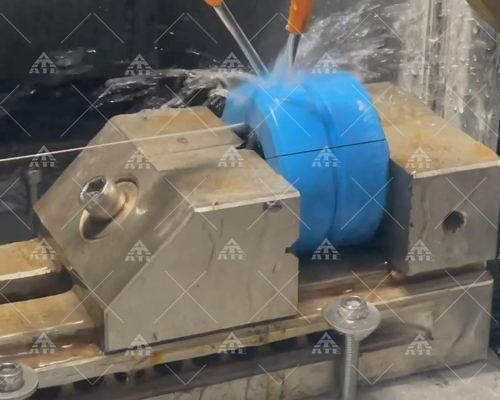

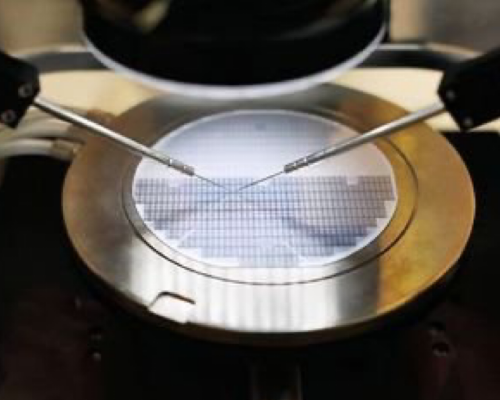

The diamond wire cutting machine uses electroplated diamond wire to reciprocate and rub against the workpiece at a speed of 0~30m/s to produce cutting to achieve the purpose of cutting. It is widely used for precision cutting of various non-conductors, crystals, semiconductors and conductive brittle and hard materials.

The diamond wire cutting machine is a contact mechanical processing, a purely physical processing method. It does not produce sparks during processing and does not change the surface properties of the processed material. The width of the slit is determined by the electroplated diamond wire. The cutting accuracy is determined by the material being cut, the cutting speed and the mechanical reasons of the machine tool. When cutting, use similar materials to try cutting several times to quickly grasp the relationship between the cutting speed and accuracy and surface roughness. Our company’s new diamond wire cutting machine adopts the technology of cutting and grinding at the same time, which has qualitatively improved the processing quality. The diamond wire cutting machine is used to cut larger materials, up to more than 1 meter, and can cut 800mm deep. The best accuracy can reach 0.03mm and the best roughness can reach 0.4μm.