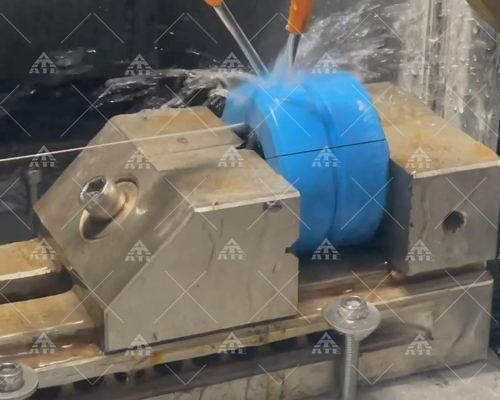

Diamond wire has many advantages: 1. It can achieve high-speed cutting, and the cutting speed can be increased to 2 times the original, and the time consumption is naturally reduced. It can complete more work per unit time, which is its biggest advantage. 2. Environmentally friendly production, the process of diamond wire only needs water or water-based cooling and cleaning liquid, which truly realizes environmentally friendly production and manufacturing. However, diamond wire technology also has many shortcomings, mainly: 1. High cost, this is still a relatively new technology, and it has not yet been popularized. The main diamond wire relies on imports. The supply of diamond wire by local companies in my country is still relatively small, so the price is relatively high. 2. The wire is too thick, resulting in large silicon wafer losses. The loss of silicon wafers is directly related to the thickness of the cutting wire. The thicker the wire, the more loss. The mainstream cutting wire is ultra-fine cutting steel wire with a diameter of about 100 microns. In actual applications, the diameter of diamond wire is about 250 microns, which is more than twice that of ultra-fine cutting steel wire. 3. There will be cut marks, resulting in low conversion efficiency of crystalline silicon cells. Therefore, diamond wire is mainly used in the rough processing of silicon wafers, such as it has been used in silicon ingot squaring. In the field of finer slicing, ultra-fine cutting steel wire is still used.